At The Specialty Manufacturing Company, sustainability is central to our operations. We’re committed to upholding our high manufacturing standards while staying focused on our dedication to sustainable manufacturing. Our approach to sustainability rests on two core pillars: reducing energy consumption and responsible waste management.

Reducing Energy Consumption

Our energy reduction strategy involves various initiatives. In 2020, we upgraded 150,000 square feet of production facilities to LED lighting, achieving a 46% energy consumption reduction, a 75% longer product lifecycle which minimized waste and maintenance costs. Smart thermostats were also installed to optimize energy use through precise temperature controls and automated schedules.

We enhanced our compressor system by using multiple units and an equalization tank to distribute the load, reducing the main compressor’s on/off cycles, significantly lowering annual energy consumption.

Machine upgrades, such as our new injection molding and CNC machines, have also improved energy efficiency. As advancements in technology for both injection molding and metal machining have improved, we’ve strategically upgraded the machines on our manufacturing floor, so we can give our customers’ the benefits of speed, agility, and quality, while also improving the overall energy consumption of our facility.

This year, machine upgrades included:

- 3 new injection molding machines

- 1 new Index MS22-8 CNC machine

- 1 new Index C200 CNC machine

A significant milestone was reached in 2018 with the installation of two 400kW rooftop solar fields comprising 2,462 panels. These fields generate 976,000 kWh of clean energy annually, producing 4,880,000 megawatts since installation, drastically reducing our carbon footprint and offsetting energy use.

Responsible Waste Management

Responsible waste management complements our energy reduction efforts. We address environmental risks associated with manufacturing byproducts through extensive recycling programs. We recycle 50,000 pounds of plastic scrap, reintroducing it to the injection molding market as regrind. Annually, 1,800 gallons of oil are recycled and repurposed, and 700,000 pounds of metals, including brass, aluminum, steel, and mixed metals, are reformed and sold as recycled content.

Our eWaste management involves partnering with OceanTech, a Minnesota-based IT Asset Disposition (ITAD) service provider with R2V3 certification. This ensures a “no landfill” policy, recycling 1,300 pounds of eWaste annually.

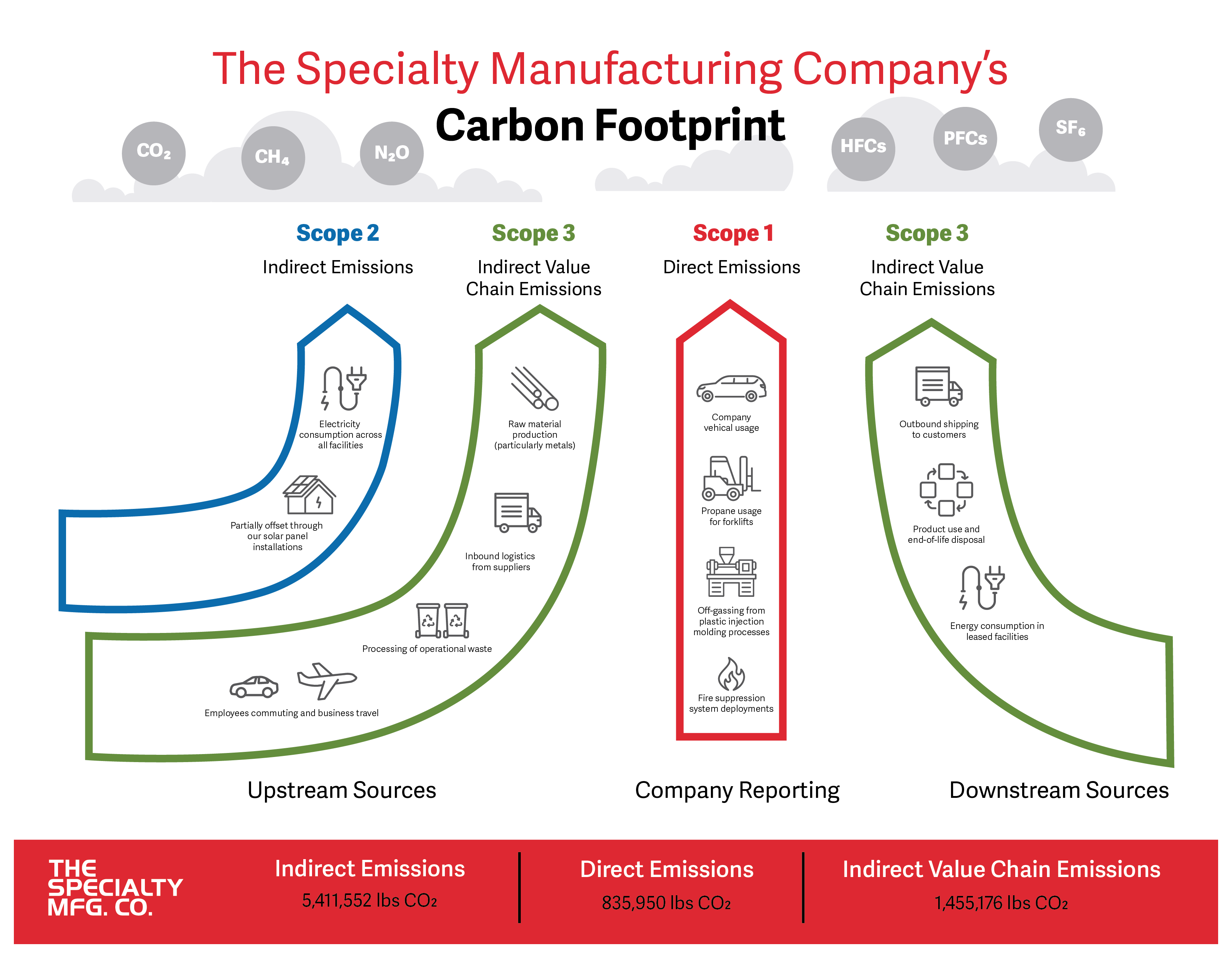

Carbon Transparency and Emissions Reduction

Manufacturers play a crucial role in reducing emissions and enhancing carbon transparency. We implement strategies like:

Energy Efficiency

Upgrading to LED lighting, smart thermostats, and efficient machinery reduces energy consumption and emissions.

Renewable Energy

Investing in solar fields decreases reliance on fossil fuels, lowering carbon emissions.

Waste Management and Recycling

Effective recycling and waste management reduce landfill waste and the need for new materials, lowering emissions.

Supply Chain Sustainability

Working with sustainable suppliers and minimizing transportation distances further reduces emissions.

How We Demonstrate Emissions Reduction

Reporting Emissions

We publish reports on greenhouse gas emissions and environmental impact.

Communicating Initiatives

We share sustainability efforts with stakeholders, including customers, employees, and the public.

Data Tracking

We track energy consumption and waste generation to support transparency.

How We Demonstrate Carbon Transparency

Quantifiable Results

We share our energy reduction and waste recycling efforts, showcasing measurable impact.

Highlighting Initiatives

We feature solar fields and eWaste partnerships on our blog and communication channels.

Strategic Investments

We emphasize investments in sustainable technologies and practices, demonstrating our long-term commitment. Environmental awareness guides our decisions, from production to company growth. Our dedication to reducing energy consumption and responsible waste management showcases our commitment to protecting the environment while maintaining high manufacturing standards. We are proud of our achievements and continue to improve our sustainability efforts.

Join us in our commitment to a greener future.

Contact us today to explore partnership opportunities or inquire about our sustainable manufacturing processes.