Celebrating 125 Years of Innovation

2025 marks the 125th anniversary of The Specialty Mfg. Co. As we reflect on this monumental milestone, we will take a look back at the incredible work ethic and leadership that shaped our beginnings and continues to guide our future. The Foundation Our story...

Sustainable Manufacturing: Our Commitment to a Greener Future

At The Specialty Manufacturing Company, sustainability is central to our operations. We’re committed to upholding our high manufacturing standards while staying focused on our dedication to sustainable manufacturing. Our approach to sustainability rests on two core...

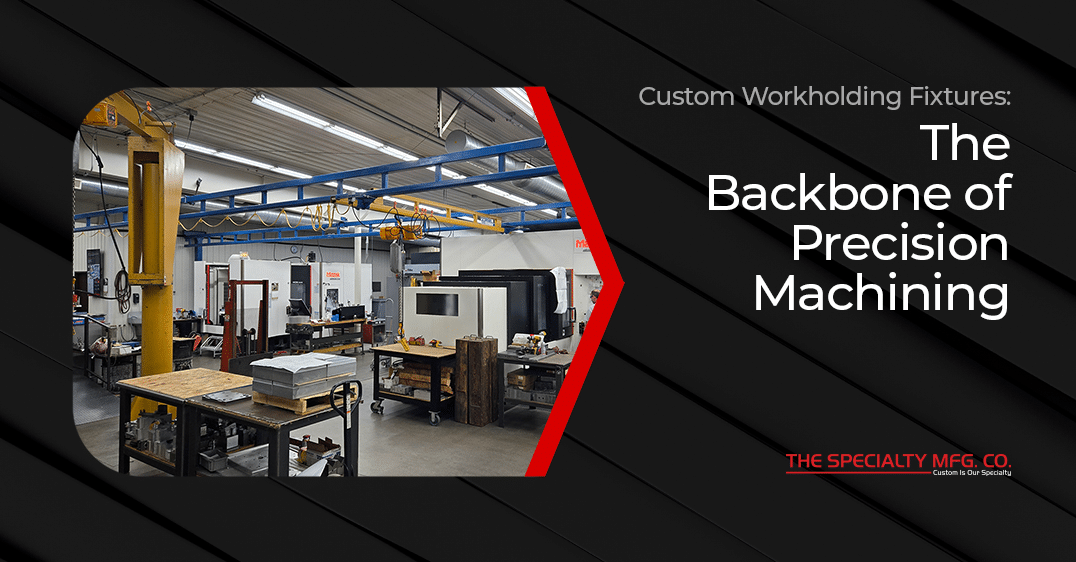

Custom Workholding Fixtures: The Backbone of Precision Machining

The benefits of a partner that understands the intricacies of workholding to deliver practical solutions. Workholding fixtures are critical in precision machining to ensure accuracy, repeatability, and efficiency and achieving tight tolerances and high-quality parts....