Specialty Mfg. News

View COVID 19 Essential Business Statement

March 25, 2020

Specialty Manufacturing announces new finish options for foot controls

February 13, 2020

Specialty Dental has announced the availability of foot controls with powder coat and matte finish options. Now your dental theatre can have Foot Controls that match the décor of your space. Specialty Dental offers these new Foot Control color and finishes in each of the four control function configurations. For details contact Specialty Dental or download this fact sheet. post with .pdf attached

Specialty Manufacturing announces the availability of Chudnow replacement valves

June 27, 2019

In the wake of the recent halting of operations by Chudnow Manufacturing, The Specialty Manufacturing Co. has announced the availability of Chudnow Manufacturing’s most widely used valves. “With Chudnow customers facing assembly line shutdowns due to shrinking inventories of critical valves, Specialty Manufacturing is ready to fill this gap and quickly provide the valves needed to keep critical assembly operations going” commented Specialty Manufacturing’s, Director of Sales and Marketing, Nate Gerdes.

Immediately available are replacements for the popular S-470 (one example pictured here). Specialty Manufacturing is able to quickly customize virtually any metal or plastic valve under 1″.

For more details on the exact Chudnow replacement valve you need, please email us today or call 651-653-0599 to reach our customer service team.

Chudnow S-470 and Specialty Mfg. replacement valve

Ezine — Solving Flow Control One Valve at a Time…

Valves are essential components for a wide range of pneumatic, fluid control and custom applications. Our metal and plastic valves are applied in the real-world applications you will read more about in this guide. Continue reading

Check Valves — A Tutorial

Exploring ideas around media flow management. Continue reading

Machine Design

Specialty Manufacturing Co. shares with us a case study on how custom-designed toggle valves improved Christensen Farms’ distribution of water to reduce waste and increase efficiency.

In 2010, the agronomy department at Midwest pork producer Christensen Farms set a goal to visit every production facility (farm) to assess and reduce water waste, which consumes manure storage capacity.

As they studied the data they gathered, they noticed a trend: The volumes of both water and manure application were higher than forecast. They set out to find out why.

As the agronomy team reviewed operations, it noticed a consistent failure of watering toggle valves in the farms. While water was delivered to the pigs, flow was inconsistent. The inconsistency influenced water waste volume, with excess water flowing over water pans and running into manure pits. Continue reading

Solar Garden

The Specialty Mfg. Co. has a rich heritage in St. Paul, Minn. that spans more than a century and four generations. A family business, the company was built on creative energy, a tradition of helping people with their products, and a commitment to supporting its community.

Specialty Mfg. also values protecting the health of our environment. As a member of the board at St. John’s University in Collegeville, Minn., the company’s president, Daniel McKeown, was interested in his alma mater’s solar garden initiative. That’s because Specialty Mfg. has more than 250,000 square feet of manufacturing space across three facilities in St. Paul, Granite Falls and New Ulm, Minn. Its largest facilities in St. Paul consist of two buildings, totaling 210,000 square feet, with rooftops that are ideal locations for solar gardens. Continue reading

The Material Importance of Fit, Form and Function

Today’s smaller and lighter automotive engines achieve greater speed than their predecessors while consuming less fuel. The simultaneous reduction of emissions and increasedmiles per gallon (MPG) figures testify to how truly efficient these engines have become. The downside of the more stringent performance requirements, however, results in a greater susceptibility for a buildup of deposits to occur in air induction and fuel systems, damaging the ratio between air and fuel. Continue reading

Value-added Engineering is a Specialty Effort

Value-added engineering simply means just that. It enhances and customizes a standard solution so that it works better; offers cost, reliability and performance benefits; or uniquely solves a long-standing challenge.

Providing value-added engineering is more than lip service and empty claims. It requires that an engineering team be in place, tasked with improving project quality and employing a high level of skill, communication and collaboration that adds value at every step along the way.

Specialty Manufacturing takes standard, off-the-shelf valves and components and adds application-specific value to designs for its customers. The ability to listen, evaluate, customize, test and deliver solutions — ranging from a minor tweak to a major redesign — defines Specialty Manufacturing and its missions. Here are four examples that illustrate the types of challenges it routinely solves. Continue reading

A Shared Philosophy Ensures Repeat Business

When Holiday House Distributing, the largest distributor of OCS, water and vending parts in North America, needed a modification to a ball valve design, there was no question that it would ask The Specialty Manufacturing Co. (SMC) to create it. Although Holiday House could have chosen to continue to perform manual assembly of the fitting, or instead farm out the assembly, experience told them that SMC would be able to reengineer an existing part and supply all the expertise needed to do so. Continue reading

The engineering behind SecureTip’s innovative saliva ejector: An interview with Specialty Dental

SecureTip was looking to improve performance of its saliva ejectors for clinicians and patients, while also reducing manufacturing costs. Read More

Innovations in Dental Tool design

See how The Specialty Mfg. Co’s. value added design and manufacturing capabilities were applied to improve the function of hand held tools for dentists, Read More

Press Releases

Looking Back: Specialty Mfg. Co. Celebrates 120 Years of Manufacturing in the Custom Valve Industry

Looking Back: Specialty Mfg. Co. Celebrates 120 Years of Manufacturing in the Custom Valve Industry

With a host of achievements to look back on, The Specialty Mfg. Co. is adding one more to the list by celebrating 120 years of service this September of 2020. A top manufacturer of custom and customized miniature valves, process control components, fixturing and pool components, Specialty Mfg. Co. (SMC) proudly serves a wide variety of industries across their home in the Midwest and beyond. Continue reading

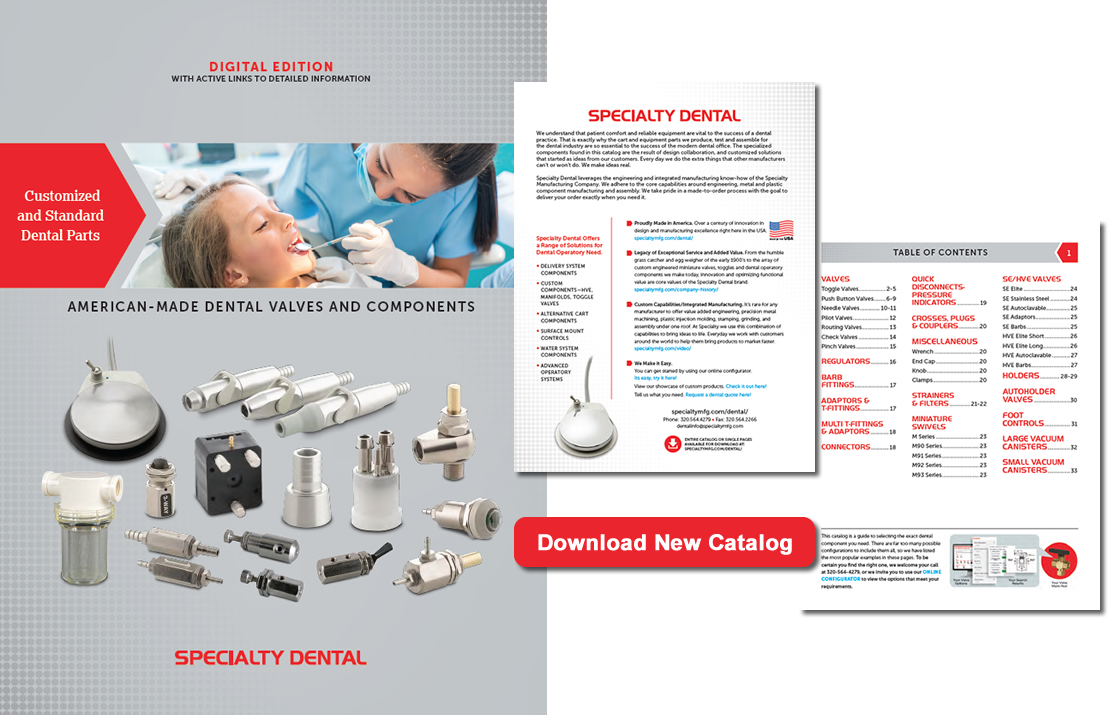

The Specialty MFG. Co. Announces Digital Catalog for Dental Supplies

The Specialty MFG. Co. Announces Digital Catalog for Dental Supplies

Specialty Dental, a division of The Specialty MFG Co., offers a wide range of quality components commonly used in the dental industry. The company’s digital catalog features 36 pages of Specialty Dental valves and products with detailed images and performance specifications. Specialty Dental, a division of The Specialty MFG Co., offers a wide range of quality components commonly used in the dental industry. The company’s digital catalog features 36 pages of Specialty Dental valves and products with detailed images and performance specifications. Continue reading

Industry’s Most Popular Suction Strainer Sizes Available As Fast As Next Day

The Specialty Manufacturing Company, a worldwide leader in custom metal and plastic valves, has announced their entire offering of suction strainers are available immediately, with all orders shipping in just two weeks and many popular sizes as fast as next day. Suction strainers provide protection in liquid or air applications by trapping debris before it can enter and damage the pump. Continue reading

Star Tribune Names The Specialty Manufacturing Company a Top Workplace for 2019

Star Tribune Names The Specialty Manufacturing Company a Top Workplace for 2019

White Bear Lake, MN, August 22, 2019 —The Specialty Manufacturing Company, a leading manufacturer in custom valve solutions, today announced that for the 3rd year in a row, it has been named a Top Workplace in Minnesota by the Star Tribune. Continue reading

Proven 5-Way Ball Valve Now Available In 3/8″ NPT For Wider Range Of Flow Control Application

The Specialty Manufacturing Company, a worldwide leader in custom metal and plastic valves, introduced the 845 Series 3/8″ five-way valve to solve complex flow control and diversion challenges across a broad range of media. Continue reading

The Material Importance of Fit, Form and Function

Today’s smaller and lighter automotive engines achieve greater speed than their predecessors while consuming less fuel. The simultaneous reduction of emissions and increasedmiles per gallon (MPG) figures testify to how truly efficient these engines have become. The downside of the more stringent performance requirements, however, results in a greater susceptibility for a buildup of deposits to occur in air induction and fuel systems, damaging the ratio between air and fuel. Continue reading

Value-added Engineering is a Specialty Effort

Value-added engineering simply means just that. It enhances and customizes a standard solution so that it works better; offers cost, reliability and performance benefits; or uniquely solves a long-standing challenge.

Providing value-added engineering is more than lip service and empty claims. It requires that an engineering team be in place, tasked with improving project quality and employing a high level of skill, communication and collaboration that adds value at every step along the way.

Specialty Manufacturing takes standard, off-the-shelf valves and components and adds application-specific value to designs for its customers. The ability to listen, evaluate, customize, test and deliver solutions — ranging from a minor tweak to a major redesign — defines Specialty Manufacturing and its missions. Here are four examples that illustrate the types of challenges it routinely solves. Continue reading

A Shared Philosophy Ensures Repeat Business

When Holiday House Distributing, the largest distributor of OCS, water and vending parts in North America, needed a modification to a ball valve design, there was no question that it would ask The Specialty Manufacturing Co. (SMC) to create it. Although Holiday House could have chosen to continue to perform manual assembly of the fitting, or instead farm out the assembly, experience told them that SMC would be able to reengineer an existing part and supply all the expertise needed to do so. Continue reading

The engineering behind SecureTip’s innovative saliva ejector: An interview with Specialty Dental

SecureTip was looking to improve performance of its saliva ejectors for clinicians and patients, while also reducing manufacturing costs. Read More

Innovations in Dental Tool design

See how The Specialty Mfg. Co’s. value added design and manufacturing capabilities were applied to improve the function of hand held tools for dentists, Read More

Looking Back: Specialty Mfg. Co. Celebrates 120 Years of Manufacturing in the Custom Valve Industry

Looking Back: Specialty Mfg. Co. Celebrates 120 Years of Manufacturing in the Custom Valve Industry

Star Tribune Names The Specialty Manufacturing Company a Top Workplace for 2019

Star Tribune Names The Specialty Manufacturing Company a Top Workplace for 2019