Custom Agriculture Valves

The Specialty Mfg. Co’s. value proposition is simple: We are specialists in metal and plastic valves under one inch, we collaborate with customers to solve the valve problems others can’t or won’t, the exact valve you need.

FEATURED PRODUCTS

FEATURED PRODUCTS

See how these valves are excelling in the Agricultural Industry

New toggle valve helps commercial pork producer improve environmental stewardship and social responsibility by reducing water waste

By improving valve quality and eliminating leaks and flow issues, The Specialty Mfg. Co. helped Christensen Farms reduce water waste.

In 2010, the agronomy department at Midwest pork producer Christensen Farms set a goal to visit every production facility (farm) to assess and reduce water waste which consumes manure storage capacity.

As they studied the data they gathered, they noticed a trend – that volumes of both water and manure application were higher than forecast. They set out to find out why.

As the agronomy team reviewed operations, they noticed a consistent failure of watering toggle valves in their farms. While water was delivered to the pigs, flow was inconsistent. The inconsistency influenced water waste volume, with excess water flowing over water pans and running into manure pits.

Equipped with this data, the department collaborated with The Specialty Mfg. Co. to solve its valve problem, improve sustainability and ensure the well-being of their pigs.

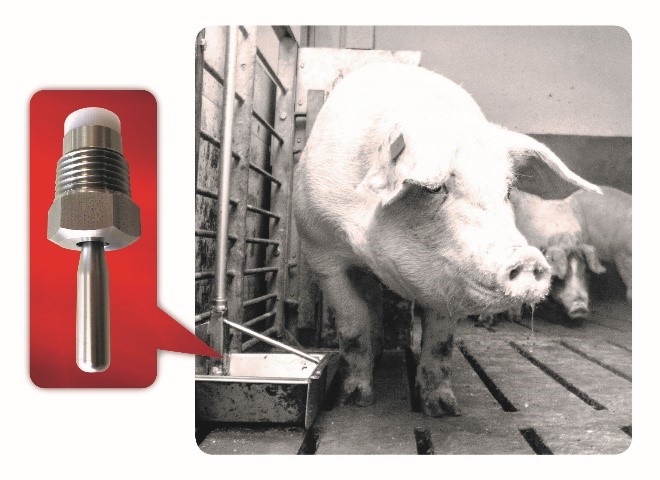

The Specialty Mfg. Co.’s custom-designed stainless steel watering toggle valve ensures proper water flow to the pigs while saving water at the same time for Christensen Farms.

Redesigning the toggle valve, one piece at a time

Christensen Farms agronomist Rick Reckow shows the redesigned water valve now used in the company’s production facilities. Reckow led the company’s internal testing and prototyping of the new valve, which was designed and manufactured by The Specialty Mfg. Co.

Headquartered in Sleepy Eye, Minnesota, Christensen Farms is one of the largest, family-owned pork producers in the United States. With nearly 1,000 employees and 1,500 contract partners, the company spans five Midwest states, which includes over 400 farms.Replacing the water valves throughout its production facilities was a large undertaking. To start, the agronomy team disassembled the current valve to identify key areas where its valves were failing.

The first piece they needed to improve was the plastic nozzle that controls the flow of water from the system through the valve. The company connected with The Specialty Mfg. Co. to develop prototypes for testing.

The existing valve had inconsistent hole sizes for water to run through, which led to varied water flow. Specialty developed a new plastic nozzle that could replace the faulty ones but still fit as a component of the existing valve.

“The new nozzles were made to the specs that we wanted, and the improved quality helped the overall valve function better,” said Rick Reckow, an agronomist with Christensen Farms, who led the company’s internal testing and prototyping of the new valve.

After initial, yearlong success with the new nozzle, Christensen Farms wanted to improve the overall valve design. While the nozzle worked well, the rest of the valve was failing because of wear and tear from the application and inconsistencies in manufacturing.

The new valves had to meet specific criteria. They had to eliminate leaks and maintain proper water flow. They also had to last seven to 10 years, and fit with a new water distribution system while still working with the current system.

With these guidelines, Specialty began custom development on a valve. The company tested the existing valves to verify issues and determine where improvements were needed. The new solution focused on precise threading, long-lasting internal springs, and a new toggle design.

The original threading was inconsistent, and Specialty calibrated its threads for proper tolerance and fit. The in-house engineering team also adjusted where the threads started on the valve to ensure the proper height between pipe and water pan.

Another major issue with the existing valve was an internal component – a rubber tube that served as a spring. When the toggle was pressed by a pig to release water, the tube would compress to allow water to flow through. However, rubber has a memory, and over time would remain compressed. This led to leaky valves, contributing to excess water use and difficulty for pigs to operate the valve.

Specialty replaced the rubber tubes with stainless steel springs to ensure reliable, long-lasting performance. The spring is centered on a brass pivot, which also makes it easier to push and activate. This is especially important because these valves are used throughout production facilities, and the smallest pigs can easily press the toggles to release water.

Similar optimizations were made to the toggles themselves. The existing valve design featured a slot on the toggle, which caused a spray when water released. The new valve uses a continuous slope instead of a slot. This allows the farm to use a lower water pressure while ensuring the water runs smoothly off the toggle and into the water pan.

The Specialty Mfg. Co. redesigned the toggle in this watering toggle valve to ensure water flows steadily into water pans at Christensen Farms.

The new watering valves from The Specialty Mfg. Co. (right) deliver smooth, consistent water to the pan, compared to the original valve (left).

“Specialty has worked with many agriculture clients over the years, but we’ve never designed a valve quite like this one. That’s part of what makes custom engineering exciting,” said Scott Rische of The Specialty Mfg. Co. “After testing and design completion, we were able to design and deliver a custom valve in just eight weeks, thanks to our in-house engineering, machining, prototyping and testing capabilities. For Christensen Farms, this collaboration created a solution that meant pigs in all stages of their life were ensured proper water flow and accessibility.”

Thanks to the new watering toggle valves used throughout its operations, Christensen Farms was able to improve its water use, reduce waste and increase its sustainable practices.

Since implementing the new valves in the water system, Christensen Farms has reduced its water waste and continued its focus on getting the correct amount of water to the pigs. The return on investment has paid off in savings throughout their system by lowering repair costs and improving nutrient concentrations in manure for crop production, and decreasing the amount of water-valve stock needing to be kept in their warehouse.

The farm also saved on manure removal costs. Because the previous valves were leaky and often sprayed outside the watering pan, water would run into manure pits below the pigs. This increased the volume or amount of manure that needed to be removed. It also diluted the manure’s nutrient concentrations, which Christensen Farms monitors because the manure is used to fertilize crops.

If the manure’s nutrients are diluted, it has to be spread at a higher volume across farmland to meet the crop’s ideal nutrient needs. Less-diluted manure can be spread at a lower rate over less acreage, helping to reduce the carbon footprint.

“We strive for excellence in care of animals and the environment, and this valve helps us in this goal,” Reckow said. “Specialty understood what we were looking for, and built us a valve to match. Now, we’re better equipped to make sure the pigs get the water they need, while creating a more sustainable process. This ultimately helps us continuously improve on our social responsibility of environmental stewardship.”

The Specialty Mfg. Co. and Christensen Farms collaborated to redesign a watering toggle valve widely used at the farm’s production facilities.

FEATURED PRODUCTS

FEATURED PRODUCTS