SafeWay, a division of The Specialty Mfg. Co., specializes in fluid control and quick disconnect solutions for a variety of industries. One of our valued customers, Cruise RO Water and Power, manufactures marine refrigeration systems for recreational and commercial watercraft. Known for their high-performance systems that use a two-phase thermal management loop, Cruise RO Water ensures reliable cooling with a 9° temperature differential, supporting boaters worldwide with easy-to-maintain, efficient solutions.

When Cruise RO Water encountered challenges with their original thermal management system, they turned to SafeWay for a reliable, customized solution.

The Challenge: Fit, Form and Function

Cruise RO Water’s original system relied on permanent connection couplings for the plate, compressor and copper tubing. These connections made service and maintenance difficult, requiring skilled technicians to braze, vacuum and refill the system with freon – a process that could cost up to $2,000. Customers were understandably hesitant to perform this necessary maintenance.

Cruise RO Water also faced extreme supply challenges. Their longtime coupling supplier experienced shortages and eventually stopped production on the specific coupling entirely. With a global customer base that includes major boat dealers and end users, Cruise RO Water urgently needed a reliable manufacturer offering couplings that met their exact specifications.

The Solution: Design Improvement Through Collaboration

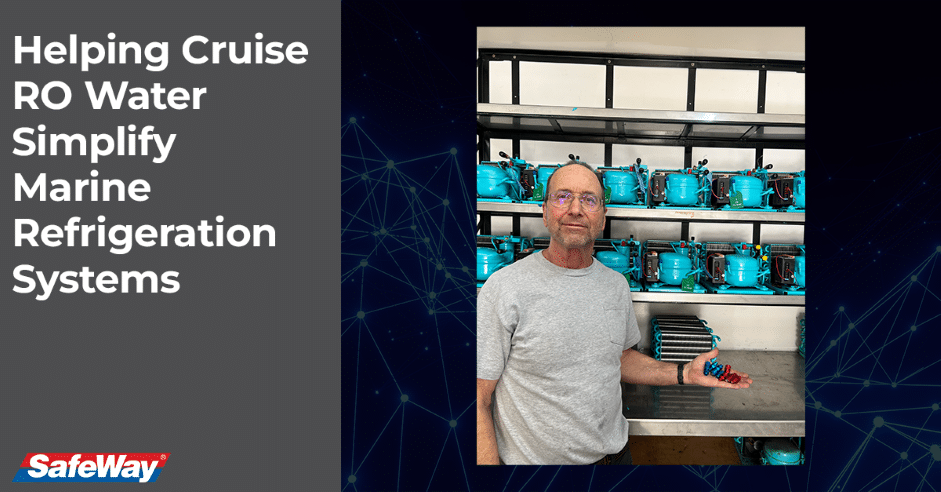

Charlie Hammel, CEO of Cruise RO Water, explored multiple manufacturers before discovering SafeWay. Already familiar with The Specialty Mfg. Co. through previous purchases of check valves and 3-way valves, Charlie recognized SafeWay’s expertise in both fluid control and quick disconnect technology as uniquely suited to solve his challenge.

SafeWay quickly identified an existing product designed for consumer computer cooling loops that could be customized for Cruise RO Water’s marine system. The team adapted the design to ensure compatibility with freon and the lubricants used in the assembly process. Samples were sent to Charlie for testing, and his detailed feedback guided our iterative improvements.

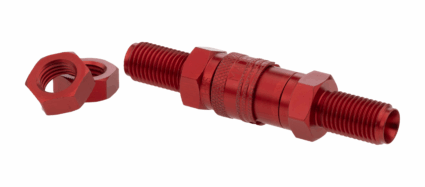

The final solution, now marketed as the SW1010 Series, provided Cruise RO Water with a robust, reliable coupling that could easily be customized for refrigerant and water-based systems alike.

The Result: Easier Installation and Maintenance

The impact was immediate. By incorporating SafeWay’s quick disconnect technology, Cruise RO Water’s systems became far easier to install and maintain. Minor repairs could now be completed on the water without special tools or risk of refrigerant loss. Color-coded red and blue anodizing made connecting the correct fluid lines straightforward, reducing installation errors and ensuring system safety. Overall, the new design simplified maintenance and improved usability, enhancing the experience for Cruise RO Water’s customers worldwide.

“Working with SafeWay has been a game-changer for us. Their team understands our needs and consistently delivers reliable solutions that make our jobs easier. We couldn’t ask for a better partner.” – Charlie Hammel, Cruise RO Water CEO

Charlie Hammel, Cruise RO Water CEO

Conclusion: Partnerships Founded on Innovation

At SafeWay, collaborative partnerships drive innovation. By working closely with Charlie and the entire Cruise RO Water team, SafeWay developed a high-quality thermal management solution that not only meets marine application needs but also informs future product development across industries.

Looking for a coupler solution tailored to your application? SafeWay is ready to solve your unique fluid transfer challenge – partner with us today!