Custom Chemical Dispensing Valves

The Specialty Mfg. Co’s. value proposition is simple: We are specialists in metal and plastic valves under one inch, we collaborate with customers to solve the valve problems others can’t or won’t, the exact valve you need.

FEATURED PRODUCTS

FEATURED PRODUCTS

See how these valves are excelling in the Chemical Dispensing Industry

Value-added Engineering is a Specialty Effort

Value-added engineering simply means just that. It enhances and customizes a standard solution so that it works better; offers cost, reliability and performance benefits; or uniquely solves a long-standing challenge.

Providing value-added engineering is more than lip service and empty claims. It requires that an engineering team be in place, tasked with improving project quality and employing a high level of skill, communication and collaboration that adds value at every step along the way.

Specialty Manufacturing takes standard, off-the-shelf valves and components and adds application-specific value to designs for its customers. The ability to listen, evaluate, customize, test and deliver solutions — ranging from a minor tweak to a major redesign — defines Specialty Manufacturing and its missions. Here are four examples that illustrate the types of challenges it routinely solves.

Engineering for Reliable Diesel Exhaust

Reducing the size of one valve often begins a chain reaction of finding additional smaller valves to complete a system. This was the case for a global diesel equipment manufacturer. When implementing a smaller footprint for a valve on a diesel exhaust system, they needed a valve that could fit into a smaller manifold.

Specialty Manufacturing worked closely to deliver a preset and tamper-proof cartridge-style regulator that could be threaded into a manifold. While a standard design and common internal components such as spool spring and seal remain, the modification centered on customized external elements including ends, threading and materials.

The modifications, while slight, are effective. Not only did Specialty meet size requirements, the relatively low-cost valve solution increased reliability.

Delivering a Unique Hydronics Valve Configuration

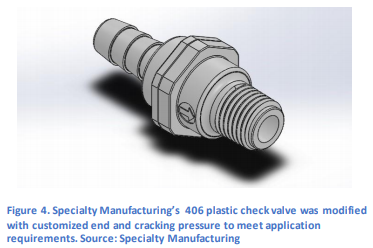

Often, value-added engineering is based on much more than a simple design change. For example, when a hydronics-system company required a compact check valve for a new application that delivered glycol and water at ambient temperature with a 0.25 crack pressure, the demanding requirements would have caused most valve manufacturers to simply pass on the opportunity.

While Specialty Manufacturing’s 406 series compact check valve met the customer’s footprint specification, it also needed a 0.25 inch male NPT (4M) outlet that could meet configuration requirements.

The resulting solution, based on substantial collaboration between Specialty and the customer, not only met performance and space requirements, but also used a poppet functionality that improved sealing properties. The long-standing customer was confident enough in Specialty’s dedication and commitment that it chose not to look at competitive options. The collaboration resulted in the creation of new injection mold tooling and prototypes plus additional testing. The customer experienced improved reliability and performance advantages with the value-added design.

Adding Value Long Term

It’s not surprising that Specialty Manufacturing sees a lot of repeat business from its client base over the long haul, in addition to attracting new customers. The value-added engineering skills and services yield unmistakable results, including greater overall efficiency and cohesive project collaboration and management for each and every project. Discover how the Specialty Manufacturing Co. can collaborate with you to solve the valve performance challenges in your application. To get started, visit https://www.specialtymfg.com/configurator/.

FEATURED PRODUCTS

FEATURED PRODUCTS